2025 Harvest – Day 4

September 9th, 2025 | Bodega

Thankfully another bright sunny morning welcomed us to the fourth day of our harvest. Having said that, if the forecasts are correct, then tomorrow could be a completely different story. (Rain is forecast to arrive around lunch time). At this time, the fruit is still very high quality and very clean; sugar content is high as we would expect from such a hot summer, and this will probably equate to a wine of around 13% Alc; a level which is fast becoming the ‘norm’ in recent vintages.

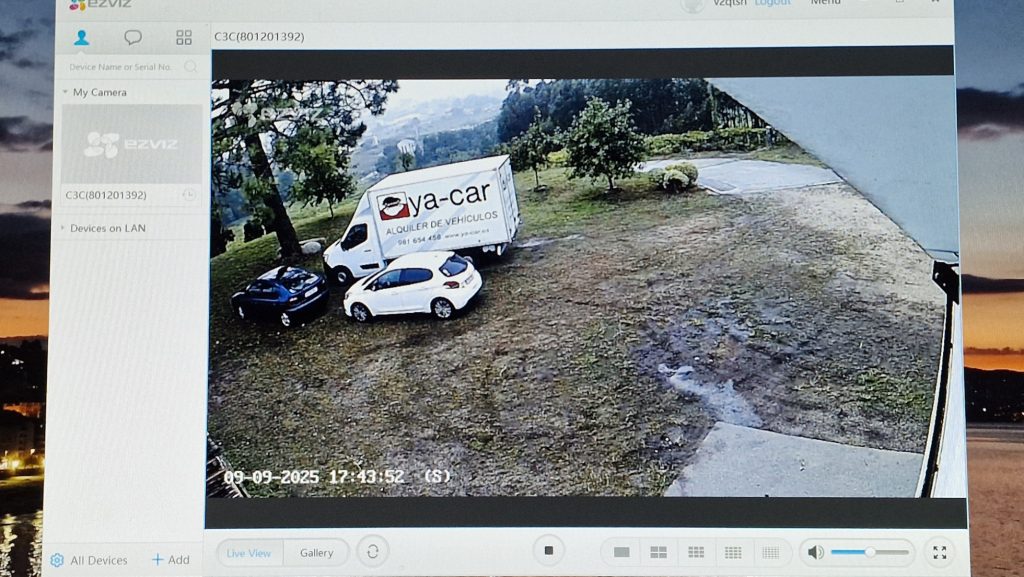

We have cameras all around our bodega, which I think most people assume are fake… but they aren’t! There is a camera at the back that I find most useful during the harvest as I can see the ramp where vehicles arrive at the grape reception. (I can also see our team sneaking out for the occasional smoke – but that’s OK, they work extremely hard). You may also notice that the ground at the back of the cellar gets very churned up by tractors and other heavy vehicles making tight turns before they reverse into our reception.

Today, there are not so many growers delivering and so our workload has eased off considerably. Despite this slowing down, we have already collected more than half of our grapes.